“It takes over 10 litres of milk to produce 1 kg of cheese;” says Marius Chiorean, Director General at De Colțești .“The process for this cheese starts with fresh cow’s milk, collected daily from local farms. After coagulation, cutting, pressing, and brining, the wheels are aged in controlled conditions, and manually cared for week after week – turned, rubbed, and monitored. The result is a complex, nutty, intensely aromatic cheese that truly reflects the landscape and patience behind it.”

For cheesemaker De Colțești – who are located în the heart of the Trascău Mountains, in Alba County, Romania – the process of making fine cheeses has until now been beset by the additional challenges of serious instability on the local power grid. Frequent power outages and voltage drops affect production, refrigeration, and machinery continuity.

Founded in 1994 as a small artisan cheese producer with a deep respect for raw materials the company has grown into a team of around 70 dedicated people who specialise in matured cheeses, using 100% natural ingredients and traditional, slow-aging methods. Annual production is around 700 tonnes and Brânză Extramaturată de Trascău is the jewel in the crown among their premium cheeses.

De Colțești recently switched to solar power to ensure that their process can continue seamlessly, without power interruption, and to avoid the use of fossil fuels and a costly generator.

“We chose to invest in a solar power system with high-capacity storage from Victron because we needed independence, stability, and efficiency;” says Marius.

Their energy system employs 12 x Quattro inverter/chargers. Groups of three Quattro’s have been configured for three-phase output. Four sets of three 15 kVA inverter/chargers have been paralleled to provide 144 kW / 180 kVA inverter power and 2400A charging capacity.

Significant roofing area on their extensive factory facility, and a large site has allowed the installation of an extensive ground- and roof-mounted PV array capable of providing 500kWp. Surplus power can be fed back to the grid thanks to a significant utility-cable upgrade.

“The project was carefully planned well in advance to minimise any impact on cheese production. The facility can’t operate without electricity for extended periods, and even slight fluctuations in room temperature can alter the composition and taste of the matured cheese worth hundreds of thousands of euros – so precision and continuity are critical.

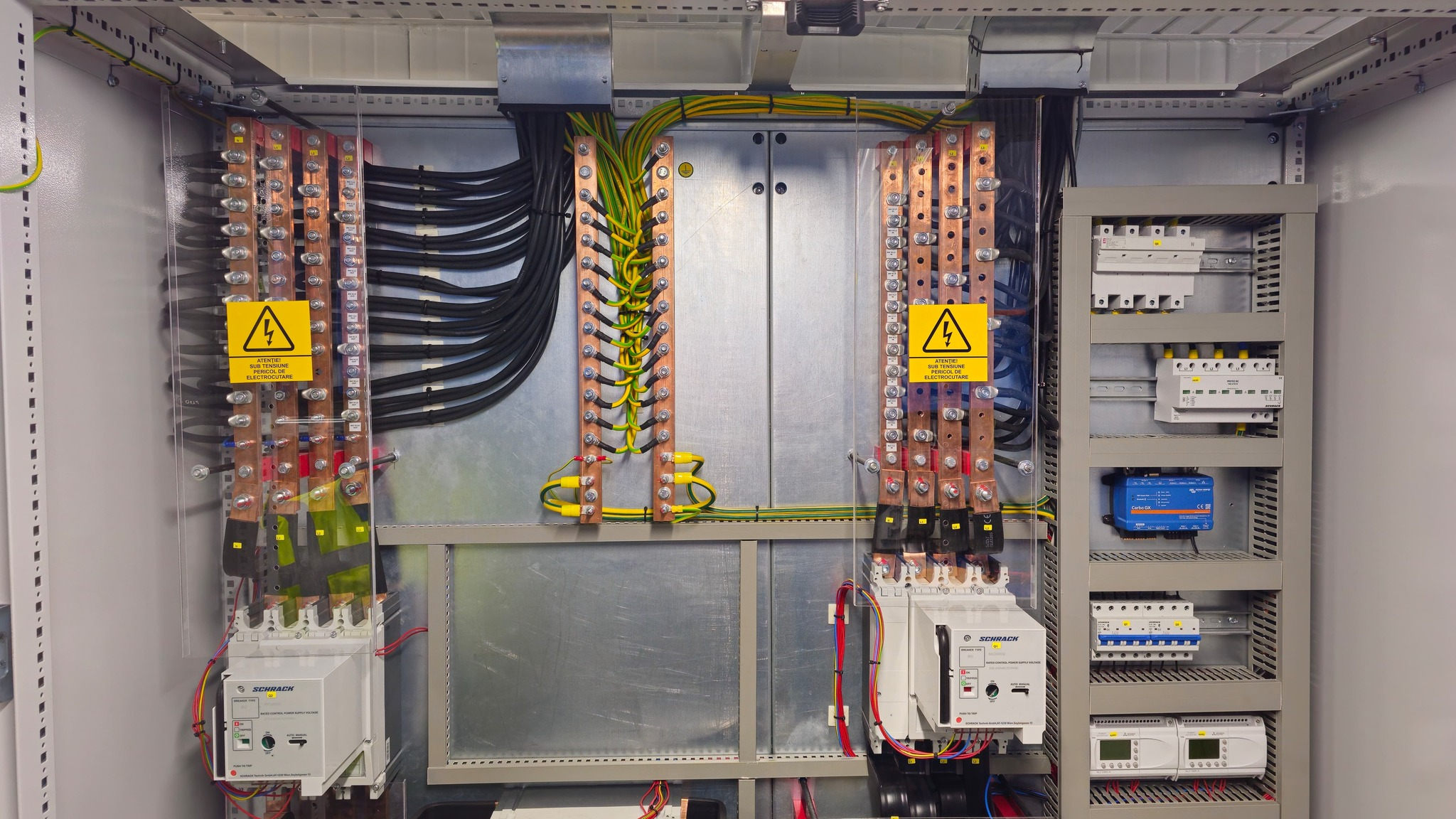

“To ensure reliability, new grid cable were installed in parallel with the existing ones – providing a much-needed upgrade to the facility’s electrical infrastructure. This was especially important given the recent installation of a 500 kW solar system, which the previous grid connection would not have been able to support.

“To minimise disruption, switchover to the new system was carried out during a single night, one weekend. Teams worked simultaneously at both ends to connect the new Victron system to the national grid. The local electricity supplier was also involved, and once the Victron system was operational and no longer restricted by the previous setup, they replaced the existing transformer with a modern, higher-capacity model.”

Credit also goes to the external team who assisted Project Manager Daniel Szomboti with this faultless operation – they were: Dumitrascu Vlad – Electrical Engineer at Schrack Technik; and Dragos Spataru – Storage engineer at Fabrica de Baterii

https://www.victronenergy.com/blog/2025/07/04/premium-cheese-maker-uses-natural-ingredients-and-solar-energy/