As the global electrification transition accelerates, high voltage battery systems are becoming critical in driving renewable energy storage and industrial automation. High voltage battery systems typically operate at voltages above 100V and feature high energy and power density, long cycle life, and fast charging capabilities. In this guide, we will discuss the main components that make up a high-voltage battery system and its common applications across a variety of industries.

High voltage battery systems are advanced energy storage solutions designed to operate at voltages above 100V – typically in the 300V- 800 V. High voltage battery systems are designed to support demanding applications such as electric vehicles (EVs), industrial equipment, energy storage systems (ESS), and marine or aerospace propulsion systems.

Compared to low voltage battery systems, high voltage solutions enable:

1. Higher power output

2. Faster charging

3. More efficient energy transfer

4. Scalability to grid and commercial use

Understanding the internal structure of a high voltage battery system helps optimize design, performance, and safety. Here are the essential components:

1. Battery Cells

At the core of every system are the battery cells, which store and release electrical energy. High voltage systems typically use lithium-ion cells based on the following chemistries:

A. NMC (Nickel Manganese Cobalt): High energy and power density, widely used in EVs.

B. LFP (Lithium Iron Phosphate): Higher safety and longer service life, commonly used in energy storage systems. For example, Pytes HV48100 uses LFP (Lithium Iron Phosphate) battery, Pytes HV48100 is a distributed high voltage energy storage system developed by Pytes, a professional solar manufacturer, which can overcome the weak power system and utilize solar energy, and it is widely used in the charging station, buildings, factories and other scenarios, to realize the functions of weak power system, peak shifting, emergency backup power and photovoltaic energy storage. peak shifting, emergency backup power, photovoltaic energy storage and other functions.

C. NCA (Nickel Cobalt Aluminum): Lightweight and high-performance, ideal for premium electric vehicles.

Cells are configured in series to achieve the required voltage and in parallel to meet current capacity demands.

2. Battery Modules and Packs

Cells are grouped into battery modules, and multiple modules form a battery pack. The pack integrates:

A. Structural support

B. Electrical connectors

C. Safety mechanisms

D. Monitoring sensors

The modular approach allows customization and simplifies maintenance and scalability.

3. Battery Management System (BMS)

The Battery Management System (BMS) ensures optimal performance, safety, and longevity of the battery. It manages:

A. State of Charge (SoC)

B. State of Health (SoH)

C. Cell balancing

D. Thermal control

E. Over-voltage, under-voltage, and short-circuit protection

4. Thermal Management System

Efficient thermal management is vital in preventing overheating and ensuring consistent battery performance. Common solutions include:

A. Liquid cooling systems

B. Air cooling systems

C. Heat pipes or phase-change materials

Well-managed temperatures extend the life of the battery and enable rapid charging.

5. High Voltage Cabling and Connectors

Specialized high voltage cables and connectors ensure safe and efficient energy transfer. These components must meet strict insulation, shielding, and temperature resistance standards to comply with industry regulations.

6. Safety Components

For safe operation, the battery pack includes:

A. Fuses and circuit breakers

B. Contactors and relays

C. Isolation monitoring devices

These components protect the system from electrical faults, overcurrent, and thermal runaways.

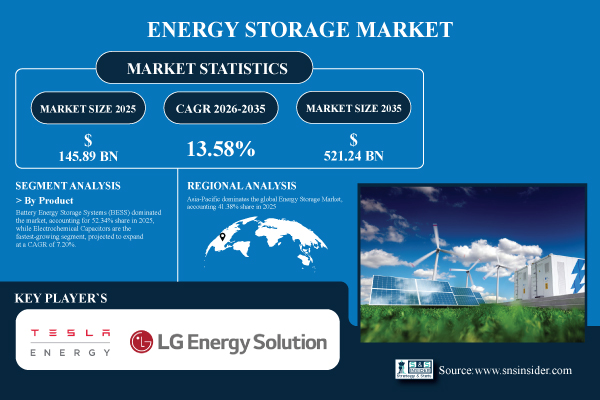

High-voltage batteries are helping electrify many industries. Here are the main application areas:

1. Energy Storage Systems (ESS)

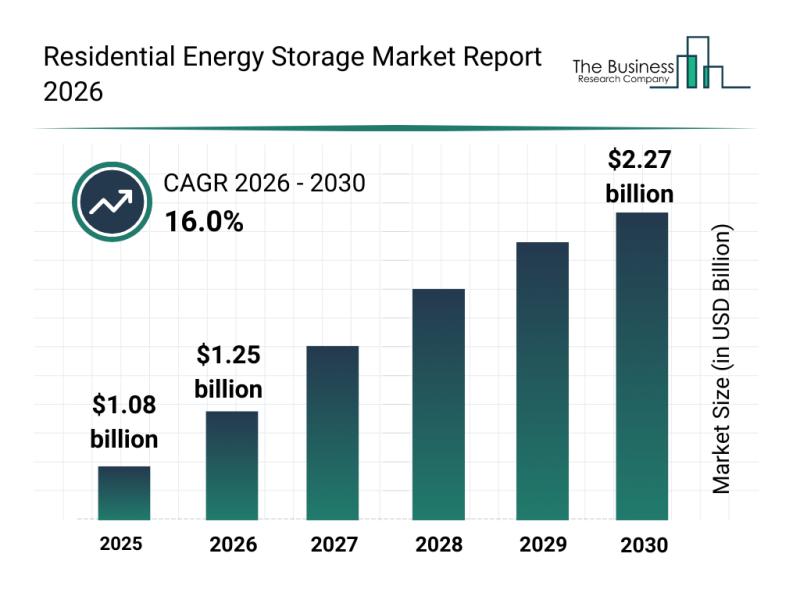

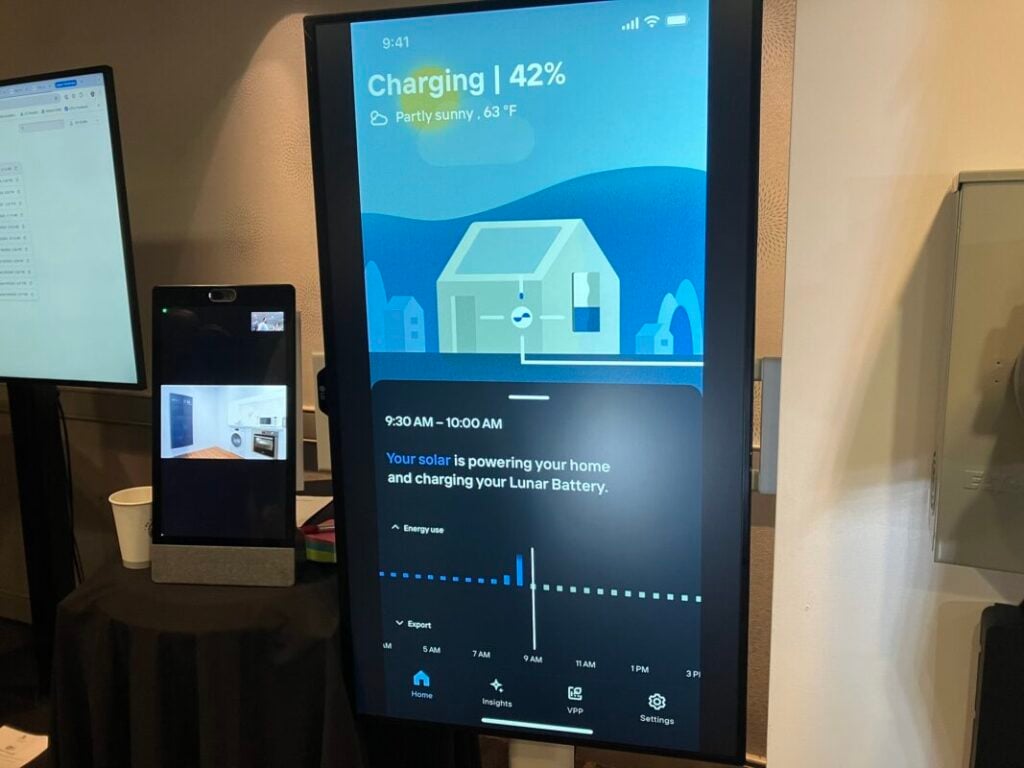

High-voltage batteries play a vital role in energy storage systems for residential and commercial use. These systems can store excess solar energy and release it during peak demand or power outages.

Residential Energy Storage Systems: Typically 400V–500V; This helps reduce electricity bills and enhance energy independence;

Utility-Scale Energy Storage Systems: 600V and above; Supports grid stability, frequency regulation, and load balancing;

Also, brands and integrators often use modular high-voltage battery racks to build flexible and scalable energy solutions.

3. Industrial and Commercial Equipment

Many types of heavy industrial equipment are being converted from diesel to electricity using high-voltage battery systems.

Applications include:

A. Forklifts

B. Excavators

C. Crane

D. Mining Trucks

Electricity can reduce emissions, lower operating costs, and achieve sustainability goals for regulated industries.

4. Marine Propulsion Systems

Electric and hybrid ships use high-voltage batteries to comply with emission regulations in port areas and coastal regions.

Applications: Ferries, tugboats, leisure boats, offshore support vessels;

Benefits: Reduced noise, zero-emission operation, efficient propulsion;

Battery packs are configured to handle long voyages and fast charging at port facilities.

As the demand for clean, reliable and efficient energy grows, high voltage battery systems like the Pytes HV48100 can provide the energy storage needed for industrial and commercial applications.

Pytes(USA) Energy, Inc. is a leader in the development of residential energy storage systems. Our goal is to leverage our 20+ years of technical expertise to help individuals save money and provide ongoing support during power outages.

If you want to upgrade your home with a solar energy storage system or deploy an industrial energy storage system (ESS), please contact Pytes to learn how we can provide you with efficient and reliable energy storage solutions.

E-mail: pytesusa@pytesgroup.com

How Photovoltaic Power Storage Batteries Change Off-Grid Life